The classic value stream analysis

Value stream analysis is one of the most important methodological skills for further developing manufacturing. An expert works with those involved in the process to analyze the material flow of a value stream step by step, recording the duration of work steps, setup times, idle times, transport times, and other factors. The dependencies between the process steps are recorded, as are influencing control variables such as batch sizes. At the same time, the information flows that are necessary for the execution of production as value creation are also recorded. This involves manual, often paper-based information transfers and the distribution of information via IT systems. The latter in particular has become increasingly complex over many years due to the digitalization of manufacturing. Not only are information flows from person to person via IT solutions important, but machines also communicate with each other via the IoT.

This analysis is usually carried out in workshops, interviews, and by inspecting the production line. This results in a documented process with standardized modeling methods. During the recording phase, particularly when carried out by external experts, problems are often identified and recorded in discussions. Potential improvements are often marked during the analysis using standardized symbols (e.g., lightning symbols). Within one to three days, intensive collaboration results in a complete, standardized process model with detailed information and potential for improvement.

Value stream design as potential realization

The collected data is then evaluated by experts and compared with standard production systems. In particular, the potential already identified in the analysis is examined in greater depth and evaluated. This analysis results in a list of potential areas with different weightings, which are recorded by the factory or production line planner and transferred to a new value stream design. This results in a new factory layout, optimized process routes, improved manufacturing and assembly steps, new responsibilities, changed processes, more transparent information flows, suitable software functionality, etc. The overall plan can be transferred into action plans or project plans.

Strengths of classic value stream analysis

The classic value stream analysis method has many strengths that can be exploited, regardless of whether a pull-based, self-regulating or push-oriented, planning-intensive production system is in place. These strengths can be summarized as follows:

- Comprehensive overview: Captures the entire flow of materials and information along the value chain.

- Identification of waste: Makes bottlenecks, downtime, unnecessary transport, and duplication of work visible.

- Create transparency: Visualize processes, dependencies, and responsibilities—easy to understand for everyone involved.

- Quickly uncover potential for improvement: Concrete indications of optimization opportunities emerge as early as the analysis process.

- Promotes cross-departmental collaboration: Brings employees from production, planning, logistics, and IT together around one table.

- Basis for strategic decisions: Provides the foundation for informed investments, automation, or digitization steps.

- Standardized methodology: Comparability and reusability through standardized symbols and process models.

- Easy introduction to lean management: Particularly suitable as a starting point for continuous improvement processes (CIP).

- Digitally expandable: In combination with IoT, MES, or AI, real-time data can be integrated and processes dynamically monitored.

Software products for classic value stream analysis

There are numerous software solutions on the market that can be divided into three categories:

| Category | Tool | Brief description | Focus / Special features |

| Specialized VSM tools | iGrafx Value Stream Mapping | Intuitive tool for modeling value streams with a focus on lean | Integration of process optimization |

| Lucidchart / Miro / Visio (with VSM templates) | Visual platforms with templates for value stream analysis | Ideal for first digital approaches | |

| LeanIX Value Stream Management | Uses value stream thinking in IT and software development | Particularly suitable for digital transformation projects | |

| Production-related MES/analysis tools | mLean / VSM360 | Combination of classic VSM with digital data acquisition from production | Proximity to production, simple implementation |

| Toolify VSM | Web-based tool for digital VSM including time recording and automated evaluation | Time data integration, easy operation | |

| VISTALOGIC Value Stream Designer | Modeling of actual/target processes with ERP/MES data integration | Deep integration into existing systems | |

| Data-driven & AI-powered solutions | Celonis (Process Mining) | Analysis of real processes based on ERP data | Not specific to VSM, but powerful for optimizations |

| Symestic / Guardus MES | MES systems with analysis functions for continuous VSM | Integration of real-time data and process data | |

| Kepware + Power BI | Combination of IoT data connection (Kepware) and data visualization (Power BI) | Creation of digital twins |

These tools offer an introduction to everything from process modeling to in-depth data analysis in production-related IT systems. They support value stream analysis in a variety of ways, but are not standalone tools in the true sense of the word and therefore cannot map digitized value stream analysis.

What is digital value stream analysis?

Classic value stream analysis already has many strengths and can be helpful in digitalization projects, but the method itself is not digitalized. It is always just a snapshot of the situation at the time of the workshop and, due to the complexity of reality, almost always only a section of a value stream, e.g., related to a product group or a sub-process.

The ideal scenario is the complete digitization of the value stream (the basic idea behind Industry 4.0) coupled with the analytical approaches of classic value stream analysis. This is only possible if the entire approach is rethought.

Digital value stream analysis starts in real time and records all necessary process data during ongoing operations. It immediately performs a value stream analysis. The focus is on the movement of materials and times in the value-adding processes. Two approaches are combined for this purpose:

- Real-time control of production

- Real-time evaluation of the value stream

What is real-time control?

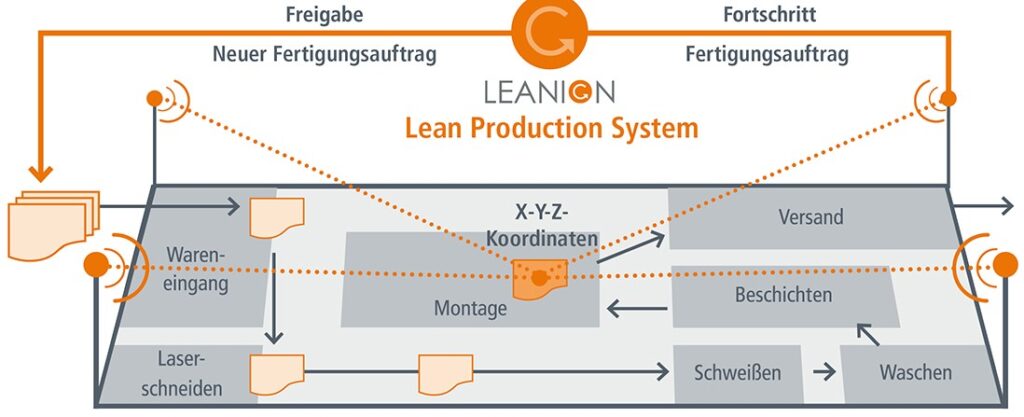

The idea of real-time control is based on a research initiative launched by Landshut University of Applied Sciences in 2012 with the LOS1 project, in which all important status information on material flows in the factory layout is displayed. The basic idea is not to provide yet another dashboard, traffic light system or status list, but rather to visualize control-relevant information directly at the point of action in a factory map.

This requires technology that can locate moving objects in real time – a so-called RTLS real-time location system. The following technology is used for this purpose:

| Technology | Location accuracy | Range | Costs | Benefits | Disadvantages | Typical applications |

| RFID (passiv) | 1–5 meters | Up to 10 m | Low | Cost-effective, no battery required | Short range, no active tracking | Logistics, access control |

| RFID (aktive) | < 1 m – 10 m | Up to 100 m | Means | Real-time capability, greater range | Battery replacement necessary, higher costs | Warehouse management, security |

| Bluetooth Low Energy (BLE) | 1–3 meters | Up to 50 m (indoor) | Low – Medium | Widely used, energy-saving | Signal interference, reduced accuracy | Indoor navigation, retail tracking |

| Wi-Fi | 5–15 meters | Up to 100 m (indoor) | Means | Use of existing infrastructure | Low accuracy, interference | Office buildings, hospitals |

| Ultra-Wideband (UWB) | < 30 cm | Up to 100 m | High | Very precise | Expensive, complex infrastructure | Manufacturing, robotics, hospitals |

| Infrared (IR) | < 1 m | Line of sight required | Low – Medium | Highly accurate position data | Line of sight required | Operating rooms, meeting rooms |

| ZigBee | 1–5 meters | Up to 100 m | Means | Mesh-ready, energy efficient | Low data rate, not widely used | industrial automation |

| GPS (outdoor only) | 2–5 meters | Global | Means | Globally available, high accuracy outdoors | No reception inside buildings | Fleet management, construction sites |

| Computer vision (cameras) | < 1 m | Room-dependent | High | Precise tracking with image data | Data protection concerns, high infrastructure costs | Smart retail, security monitoring |

| Wirepas Mesh | 1–5 meters (typical) | Scaled (mesh network) | Low – Medium | Scalable, energy-efficient, decentralized architecture, no gateways required | Lower accuracy than UWB, new technology | Warehouse logistics, industry, smart buildings |

Real-time control uses these technologies to locate individual order objects, such as containers, individual materials, logistical objects, such as forklifts, tugger trains, or other mobile bottleneck resources, such as tools and test equipment.

The objects to be tracked are linked to the respective tag, allowing their location and any movement to be recorded in real time. The technology used depends on the degree of accuracy and the tracking frequency. In practice, UWB is primarily used due to its accuracy and frequency, with BLE and Wirepas Mesh being used in peripheral areas.

Depending on the available target data, delayed orders, deviations from the work plan, or unstable process steps can thus be displayed in real time with all the necessary information in the respective factory map. Responsible employees are alerted and can react immediately when an incident occurs and actively intervene in production.

This technology is essential for digital value stream analysis. The movement and status data collected is analyzed immediately and presented in the context of value creation.

How does digital value stream analysis work?

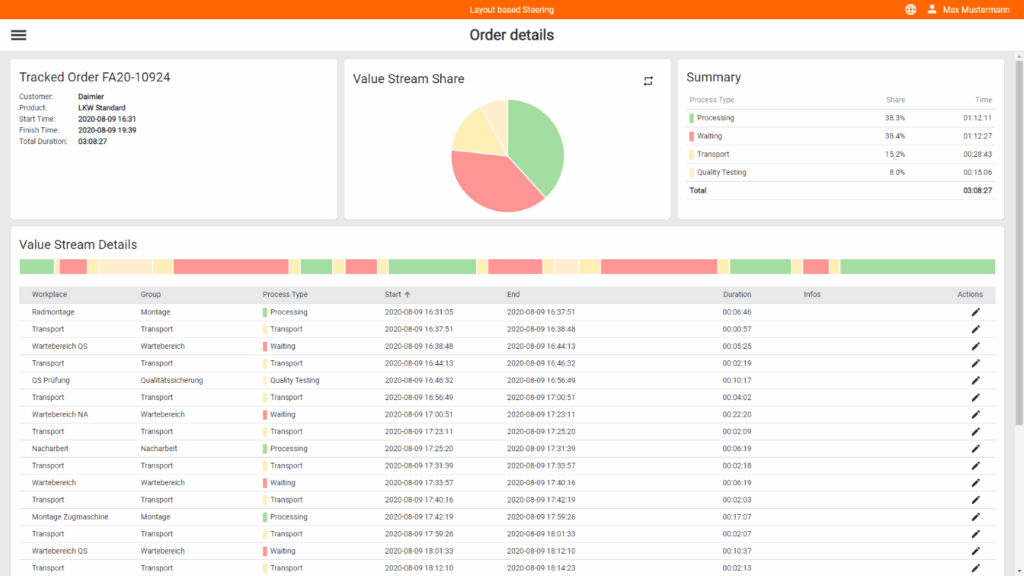

In real-time control, so-called GeoFences are defined on the factory map. These are freely definable zones covering any area in a production facility. Typical GeoFences are, for example:

- Assembly Workstations

- Machines

- Waiting areas before and after process steps

- Storage locations such as supermarkets, etc.

- Transport areas such as corridors, conveyor belts, etc.

- Quality Assurance

The value-adding GeoFences are usually derived from the work schedules.

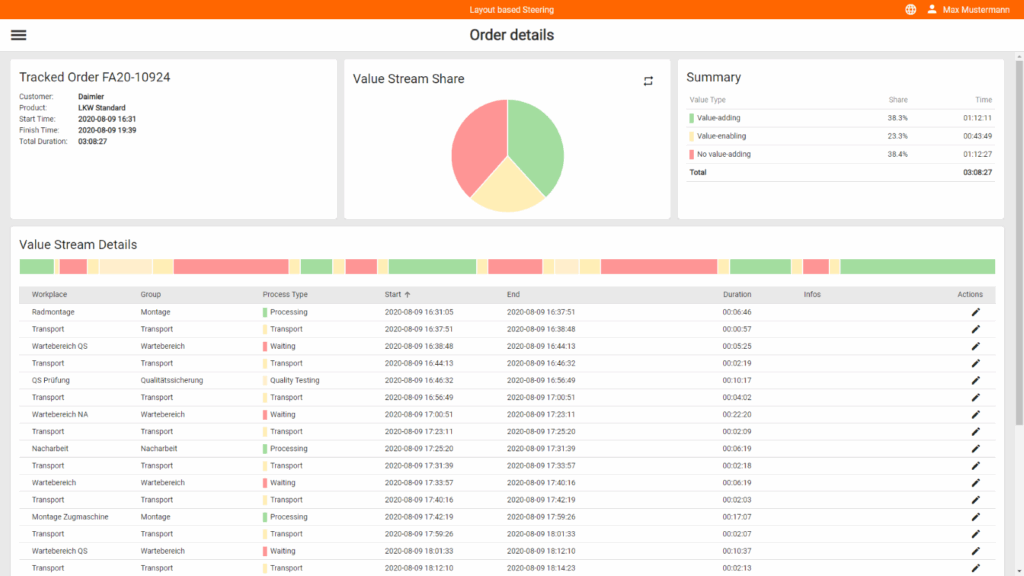

These GeoFences can be assigned a wide variety of properties, such as process groups, lines, activity types, and so on. The value-adding property is decisive for value stream analysis:

- Value-adding activity

The product becomes “more valuable” as a result of the activity, e.g., when assembling products that incorporate labor, materials, and additional functionality.

- Non-value-adding activity

The product does not become “more valuable” as a result of the activity, because no changes are made to the product, e.g., in a waiting area in front of a machine.

- Value-adding activity

The product does not become “more valuable” as a result of the activity, but the activity is necessary to enable further process steps, such as the cooling time after a kiln.

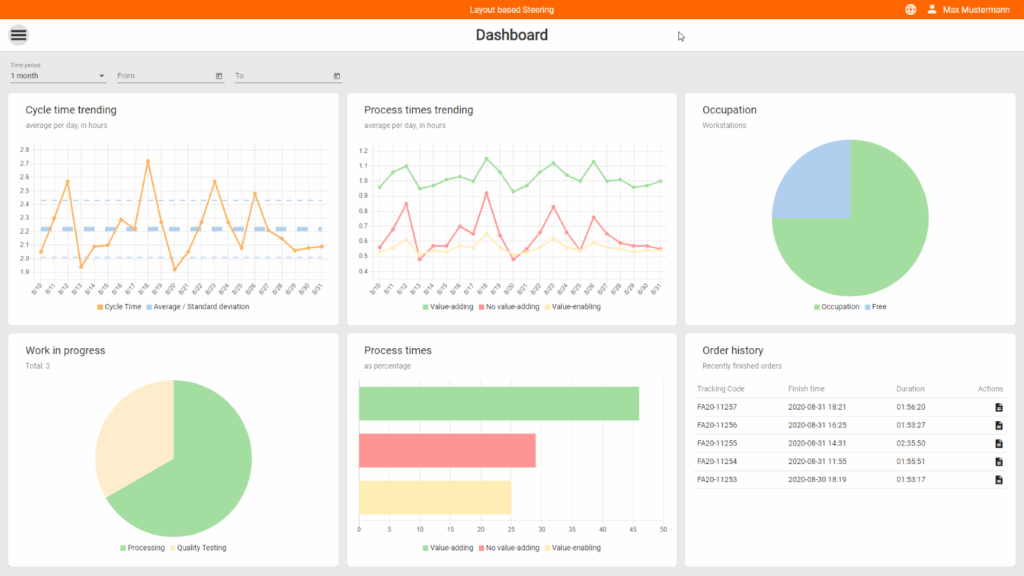

Using real-time control, the digital value stream analysis determines the current value creation status for each individual production order every second and displays it in two ways:

Real-time value creation

The current degree of value creation in production can be displayed at any given moment using status indicators, such as

- Number of activities broken down by value added

- Time quotas for current activities by value added

- Trend analyses of value added

- Deviation reports by value added

Analysis of the complete value stream

A detailed value stream analysis exists for every production order at all times. The complete value stream is digitized at all times. This leads to the following evaluation options:

- Analysis of a single value stream

- Analysis of order groupings, e.g. by customer

- Analysis of value-added classes, e.g. according to value-adding activities

- Analysis of process groups, e.g. according to prefabrication

- Benchmark analyses

- Trend Analyses

Advantages of digital value stream analysis

Digital value stream analysis is not comparable to the approaches listed above in terms of methodology and IT implementation. In addition to the advantages of active real-time production control, which serves as the basis for digital value stream analysis, the following five advantages should be evaluated individually by each company:

- Current value added

Responsible employees can see the degree of value added and how it has developed, and act accordingly.

- Complete transparency

Every order run (single value stream) is recorded at all times in every possible status.

- Increased response speed

Real-time data, trends, and deviations enable immediate action at the scene of the incident.

- Focus on the essentials

The information provided by value stream analysis reveals the most important potential in a commercial operation – namely, the degree of value added. By focusing on this information, more in-depth root cause analyses can be carried out and optimization potential identified.

- Scope of digitization

The seamless recording of all value streams enables further processing options, such as process documentation of digital twins, complex overall analyses with AI, or even the introduction of value stream-based process cost accounting.

Conclusion

Digital value stream analysis is a completely new technological approach based on decades of proven methodology. It does not replace other methods and IT solutions, but rather complements them with a whole new perspective that was previously unattainable.

Digital value stream analysis focuses on the essentials: “Are we working in a value-adding way, or are we wasting our valuable resources?”

Author of this expert opinion

Klaus-Oliver Welsow is managing partner of UWS Business Solutions GmbH, a consulting firm specializing in digitalization. He began supporting lean initiatives in the automotive industry from an IT perspective in the early 1990s. After studying business informatics with a focus on production control, he founded UWS Business Solutions in 2003 together with his business partner André Unger. Since then, the two entrepreneurs and their team have been supporting large-scale digitalization projects and lean management projects and have developed the LEANION lean production system.