Smart Factory

Leverage digitized processes for live insights, lower costs, and reduced downtime.

Today's Challenges

Paper-based Documentation & Inefficient Process Monitoring

Paper-based documentation slows down digital transformation and relies on outdated, error-prone methods. Traditional process monitoring also lacks real-time insights into work-in-progress (WIP) and completed workflows, leading to delayed decision-making and reduced productivity.

Ensuring Process Quality Control

In modern production environments, quality assurance is indispensable. However, delays, sequence errors, and blocked materials jeopardize supply chain transparency and compliance with standards. Key metrics such as order delays, error rates, and workload overviews are crucial for maintaining consistent quality assurance.

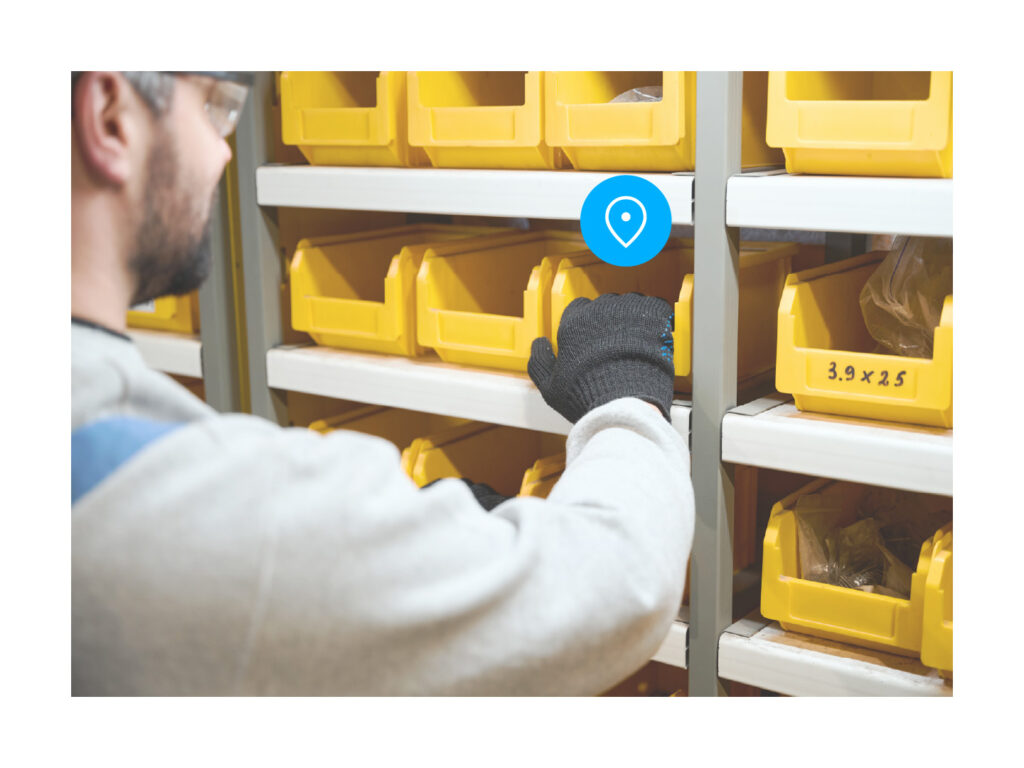

Minimize Search Times

Search times impact productivity. Quickly locating tools, materials, or equipment keeps employees focused on their core tasks, reducing downtime and delays. Efficient access to information minimizes bottlenecks and keeps production on track, enabling teams to consistently meet their targets.

Error-Prone Material Replenishment Planning

Manual material replenishment processes often result in costly errors, delays, and operational disruptions. Avoiding these mistakes is essential to maintaining uptime and ensuring a continuous, efficient production flow.

Siloed Business Systems

Optimized manufacturing requires seamless communication between ERP, WMS, and MES systems. Without integration, data silos, inventory issues, and workflow inefficiencies arise, hindering effective asset and order management on the shop floor.

Solutions For Your Smart Factory

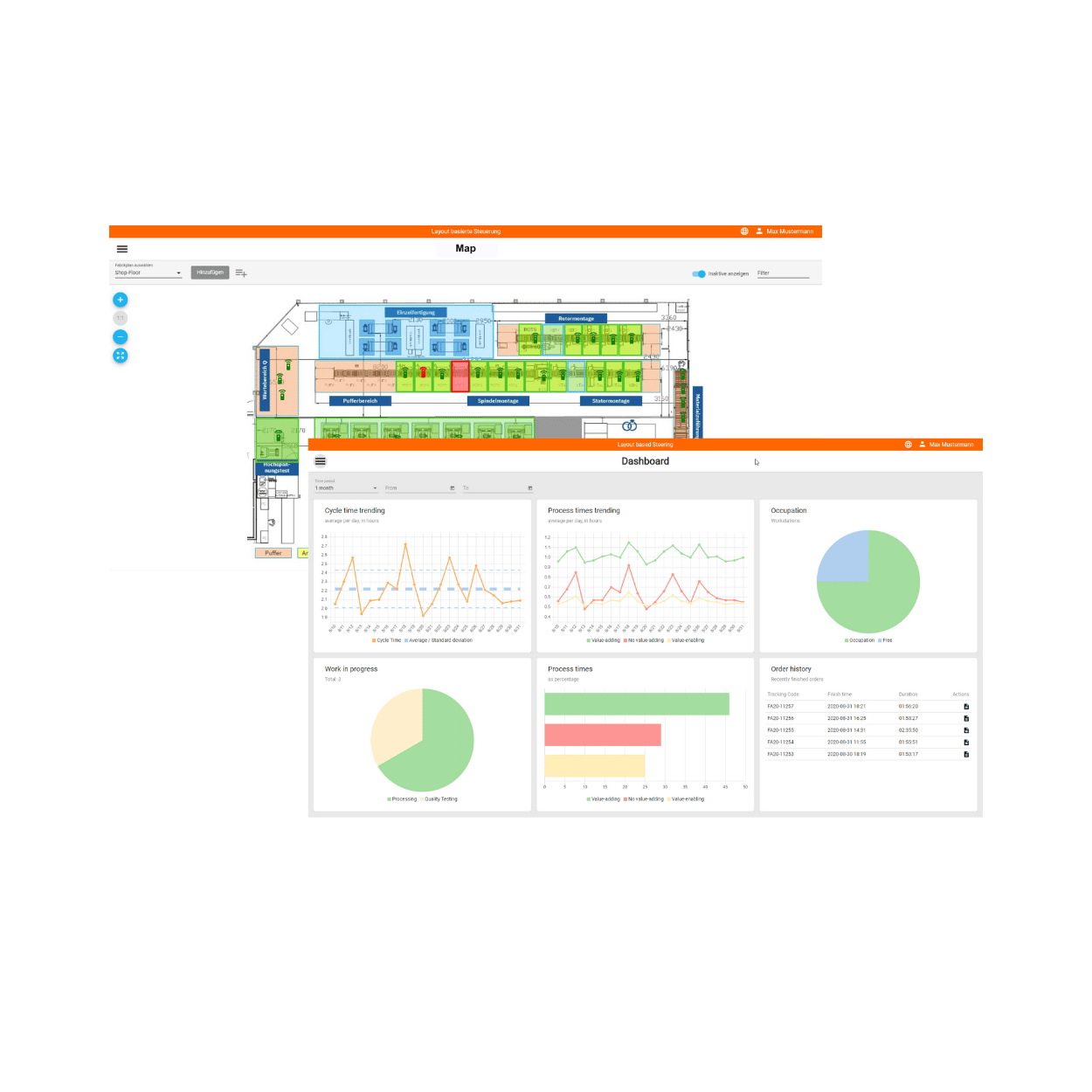

Real-Time Order Tracking & Automated Process Management

Experience full transparency with real-time order tracking. Attach Cavea Wirepas Mesh-based ESL tags (ePaper) to each handling unit assigned to a production order, and watch your shop floor come to life with live overviews.

Say goodbye to paper: Process information is automatically displayed on each ESL tag (ePaper), guiding employees through every step. With intuitive buttons, operators can directly interact, report issues, or share updates in real-time.

Cavea’s software platform provides a live view of every movement along the production line, giving management the insights needed for quick, informed decisions. With seamless integration into ERP, MES, and WMS systems, including the SAP connector for automated SAP postings, your entire operation stays connected and optimized.

Key features:

- Trackable ESL tags with relevant process information and direct interaction via physical buttons

- Real-Time Order Overview for Complete Transparency

- Seamless Integration into Your Business Systems

Asset Tracking

Effortlessly locate all essential tools and equipment. With Cavea’s intuitive software, you can view the live position of all high-value assets in one place—eliminating time-consuming searches. Empower your team to focus on what matters most, with the confidence that everything they need is just a glance away.

Key features:

- Live Location Overview for Tools, Equipment, and Other Relevant Assets

- User-Friendly Software for Shop Floor Employees

- Seamless Integration into Your Software Landscape for Inventory Management

Material Replenishment (eKanban)

Key features:

- Automatic Replenishment Notifications for Continuous Material Flow

- Smart eKanban System for Precise Inventory Management

- Effortless Integration with Your ERP and Inventory Applications

Automated Process Quality Control

Key features:

- Real-Time Alerts for Immediate Action on Misplaced or Delayed Assets

- Automated Monitoring for Effortless Process Quality

- Live Notifications that Inform Teams and Keep Processes on Track

Advanced Analytics

Key features:

- Gain new insights through location data

Digital Value Stream Analysis – Analyze and optimize your processes

We track your processes for four weeks. Using this objective data, we uncover hidden efficiency potential and lay the foundation for leaner, automated processes. No guesswork. Just measurable facts.

Your Advantages

Our solutions deliver benefits that ensure a fast ROI.

95% Fewer Manual Order Recognition Scans

Automatic bookings eliminate errors and save time.

2 Hours Saved Per Day And Employee

20% More Efficient Space Utilization

Analysis of over- and underutilized areas enables more efficient space usage.

100% Paperless

Achieve Complete Traceability

Gain a complete overview of asset movements and usage in your workspace, enhancing decision-making and resource allocation.

Improved Process Quality

By automatically detecting issues and triggering alerts and notifications, the quality of your processes is improved, and uptime is increased.

How It Works

Cavea Hub & Software

Leverage our comprehensive Cavea software suite for data analytics, process automation, or take advantage of the APIs to transfer data directly into your systems (ERP, WMS, MES).

Partner Ecosystem

Strong partner ecosystem with system integrators and specialized software and hardware providers.

omlox Standard

Break free from vendor lock-in with the open omlox standard. Seamlessly integrate position and sensor data from multiple providers.

Hardware Solutions

Experience our proven and industry-leading hardware, already trusted by over 28,000 customers.

Solution Architecture

Cavea offers you access to several tracking technologies.

Thanks to the open omlox standard, we are able to seamlessly integrate other tracking technologies from our partners or solutions that you already use with the Cavea Hub.

With Cavea cloud and Cavea edge, you can choose whether you want to run the software applications in our secure cloud environment or on a local server.

What other Companies say

"Our long-standing partnership with Cavea stands for reliability and forward-looking innovation. The Mesh Starter Kit is an outstanding example of this: it enables companies to quickly and easily test the performance of Wirepas Mesh technology in conjunction with the Cavea solution portfolio - and thus immediately discover real added value."

Thomas Weißhaupt

"The innovative Cavea hardware provides precise positioning data that is seamlessly integrated into our DeepHub thanks to the omlox API. This enables our customers to seamlessly locate their assets, automate business processes and conserve resources."

Dr. Matthias Jöst

“Cavea displays precise movement and position data of objects on our employee-focused application. This enables our customers to realize significant productivity gains and process improvements.”

Jan Lachenmayer

"By combining UWB and Cavea Wirepas Mesh technology, we create a versatile solution that merges the highest precision with scalable connectivity. This enables real-time visibility of assets and maximizes ROI for our customers."

Erik Mademann

“The seamless integration within our IoT platform, combining ESLs with Cavea’s location solution, enables paperless manufacturing and sustainable process automation. Together, we create complete transparency and more efficient processes for our customers.”